What is a chimney flue?

What materials should be used to install a chimney flue?

In the past, pipes made of asbestos or fibre cement were used since the material has very good insulative properties. These pipes are now well known to be very harmful to our health and so have not been used for many years. When removing old drain or chimney pipes that might be made of asbestos, it is important to employ a certified company to remove and dispose of it in the correct way.

The most common materials used nowadays for chimney flues are steel or stainless steel. Although there are many brands and materials available at varying prices, it is important to know which materials should be used in each scenario. There are various factors that would influence the choice of material such as the type of stove or fireplace and the location. Usually, a single wall steel or stainless steel pipe which is not insulated is used to connect the stove or fireplace to the main chimney. For aesthetic purposes when installing a freestanding appliance such as a log stove or pellet stove, we would usually use a pipe that has been coated with a black heat proof paint. This should then be connected to an insulated flue pipe.

Why use insulated flue pipes?

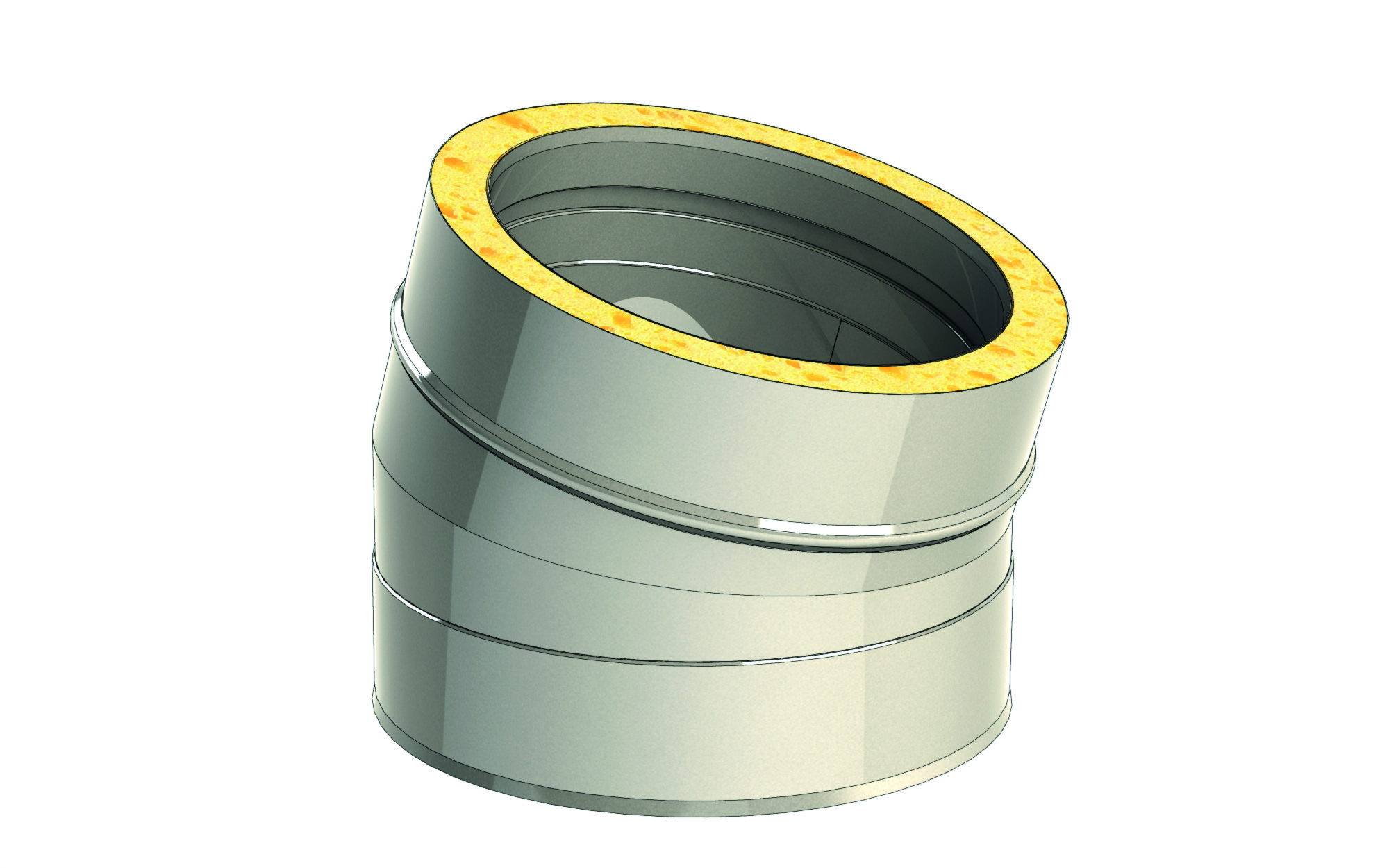

A chimney flue works on the principle of Stack Effect which occurs since the air outside is substantially lower in temperature than the hot exhaust gasses inside the flue. This causes the warmer air inside to rise up and out of the chimney flue. Therefore, when the temperature inside the flue is not hot enough when compared with the outside temperature, the function of the chimney flue will be greatly affected. Insulating the flue pipes helps to keep the flue gasses hot and maintains a good draft. Keeping the chimney warm by using double wall insulated flue pipes also helps keep the combustion in the fire box cleaner and emits less fumes or soot.

One of the big problems with using single wall pipes which are not insulated is the condensing of exhaust gasses on the inside of the flue. This occurs since the air outside is cooling the fumes inside the flue – the amount of condensation increases when the flue is passed outside the house since the temperature is lower but can still happen when the flue is passed inside the house. Contrary to what some installers might lead you to believe, adding a drain is not a solution since the condensing of exhaust gasses usually leads to a build up of sulphuric acid which is highly corrosive to steel and stainless steel. The solution is to prevent the build up of condensation in the first place by insulating the flue.

Other factors to consider when installing a chimney.

Since a chimney flue relies on a natural draft created by the Stack Effect, it is important not to restrict the flow of smoke. Bends or elbows in a chimney should be kept to a minimum and should be installed as straight as possible – 45 degree bends are better than 90 degree bends although there are exceptions. Apart from restricting the draft, sharp bends in a flue also collect more soot which greatly increases the chance of a chimney fire. Long horizontal sections in a flue have the same effect. A problem we sometimes find in chimneys which have not been installed in the correct way is lack of access for sweeping the chimney – if a 90 degree angle is required in a flue, it should be installed in such a way that allows access to the flue for sweeping and inspection.

Chimney flue draft is also affected by length / height and size. Generally, the taller a chimney is, the more it will draw. A larger diameter also increases the draft. The manufacturer of the stove or fireplace would usually give a guide as to the diameter and length needed for the flue but an experienced installer should know if any changes in flue sizing are possible or even necessary.

Is it possible to connect more than one stove or fireplace to one chimney?

Feel free to contact us with any questions you might have. We sell chimney pipes and related accessories and offer chimney installation and sweeping services.